Precision Metal Processing for Industrial Applications

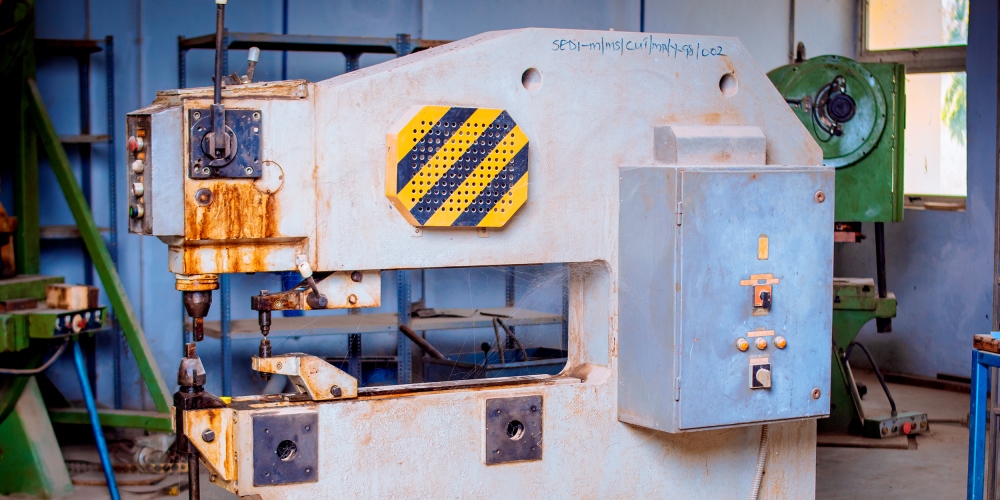

The Hydraulic Iron Worker Machine Workshop at SEDI Minna is a specialized facility dedicated to high-precision metal fabrication, cutting, punching, shearing, and notching. Our workshop is equipped with state-of-the-art hydraulic iron worker machines designed to handle various metalworking tasks efficiently, safely, and cost-effectively.

With the growing demand for versatile and high-capacity metal processing solutions, our facility supports manufacturers, metal fabricators, construction companies, and industrial engineers by offering fast, accurate, and energy-efficient ironworking services. Whether you need structural metal fabrication, industrial component manufacturing, or custom metal shaping, our hydraulic iron worker machines guarantee high productivity and superior-quality output.

Capabilities of Our Hydraulic Iron Worker Machine

Our hydraulic iron worker machines at SEDI Minna provide multi-functional metal processing capabilities, including:

1. Precision Metal Cutting & Shearing

- Efficient cutting of steel plates, rods, and angle iron.

- High-speed shearing with minimal material wastage.

- Smooth and burr-free cuts for precise metal fabrication.

2. Punching & Hole Drilling

- Accurate hole punching for metal sheets and structural steel.

- Custom hole sizes with clean edges and minimal deformation.

- Rapid punching for high-volume production requirements.

3. Notching & Shaping

- Precise notching of metal plates, pipes, and profiles.

- Enhanced accuracy for seamless joint formations.

- Ideal for industrial and construction applications.

4. Bending & Forming

- Hydraulic-powered bending for custom metal shapes.

- Consistent angles and curves for structural applications.

- Reduced need for secondary finishing processes.

5. Versatile Metal Fabrication

- Capable of handling various metals, including mild steel, stainless steel, and aluminum.

- Multi-purpose functionality for diverse industrial applications.

- Highly efficient processing to reduce labor costs and time.

Industries We Serve

Our Hydraulic Iron Worker Machine Workshop at SEDI Minna provides high-precision metalworking solutions for various industries, including:

✔ Construction & Structural Engineering – Cutting and punching steel beams, frames, and support structures.

✔ Manufacturing & Industrial Fabrication – Producing custom metal components, enclosures, and machine parts.

✔ Automotive & Aerospace Engineering – Fabricating metal brackets, panels, and structural reinforcements.

✔ Energy & Power Industry – Processing metal components for power plants, pipelines, and electrical enclosures.

✔ Agricultural & Heavy Machinery – Manufacturing precision-cut metal parts for farm equipment and machinery.

Why Choose SEDI Minna’s Hydraulic Iron Worker Solutions?

✅ High Precision & Efficiency

- Superior hydraulic power for clean and accurate cutting.

- Fast processing speed for high-volume production.

✅ Multi-Functional Machine Capabilities

- Performs multiple tasks in a single operation – cutting, punching, notching, and bending.

- Eliminates the need for separate machines, reducing production costs.

✅ Durability & Reliability

- Heavy-duty machinery designed for long-term industrial use.

- Low maintenance requirements with extended service life.

✅ Eco-Friendly & Cost-Effective

- Reduces metal waste with optimized cutting efficiency.

- Energy-efficient hydraulic system for lower operating costs.

✅ Custom & Scalable Production

- Suitable for both small-scale and large-scale manufacturing.

- Adaptable to diverse metal processing needs.

Research & Development in Metal Processing

SEDI Minna’s research team is actively involved in developing advanced metal fabrication techniques, ensuring improved accuracy, reduced material wastage, and enhanced structural integrity. Our R&D initiatives focus on:

✔ Optimizing hydraulic iron worker machine performance for increased productivity.

✔ Innovating metal shaping and forming techniques for new industrial applications.

✔ Enhancing metal waste recycling and sustainable fabrication processes.

Training & Capacity Building

We offer technical training programs in hydraulic iron worker machine operation and maintenance, including:

✔ Metal Cutting & Shearing Techniques

✔ Hole Punching & Precision Drilling

✔ Metal Notching & Structural Fabrication

✔ Safety & Quality Control in Metal Processing

Our training equips participants with industry-relevant skills and practical knowledge to advance their careers in metal fabrication.